| Feed in size |

0-560 MM |

| Capacity |

45 – 2130 TPH |

| Application |

Widely used in metallurgy, construction road, railway and commercial concrete industry sand and gravel aggregates. |

| Scope of Application |

It can crush a variety of ores and rocks medium and above medium hardness, such as granite, diabase, basalt, pebble, limestone, dolomite, metallic ores and non-metallic ores, etc. |

| Machine Introduction |

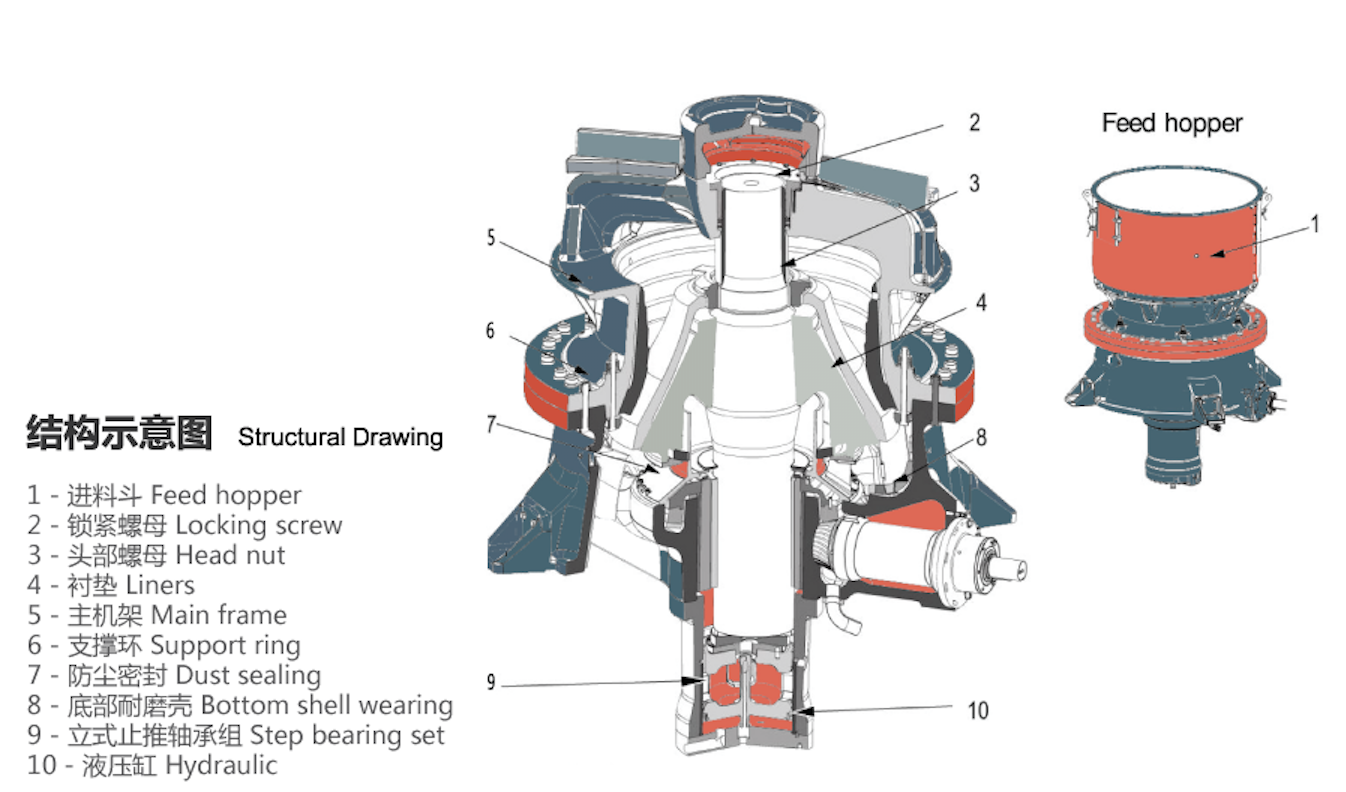

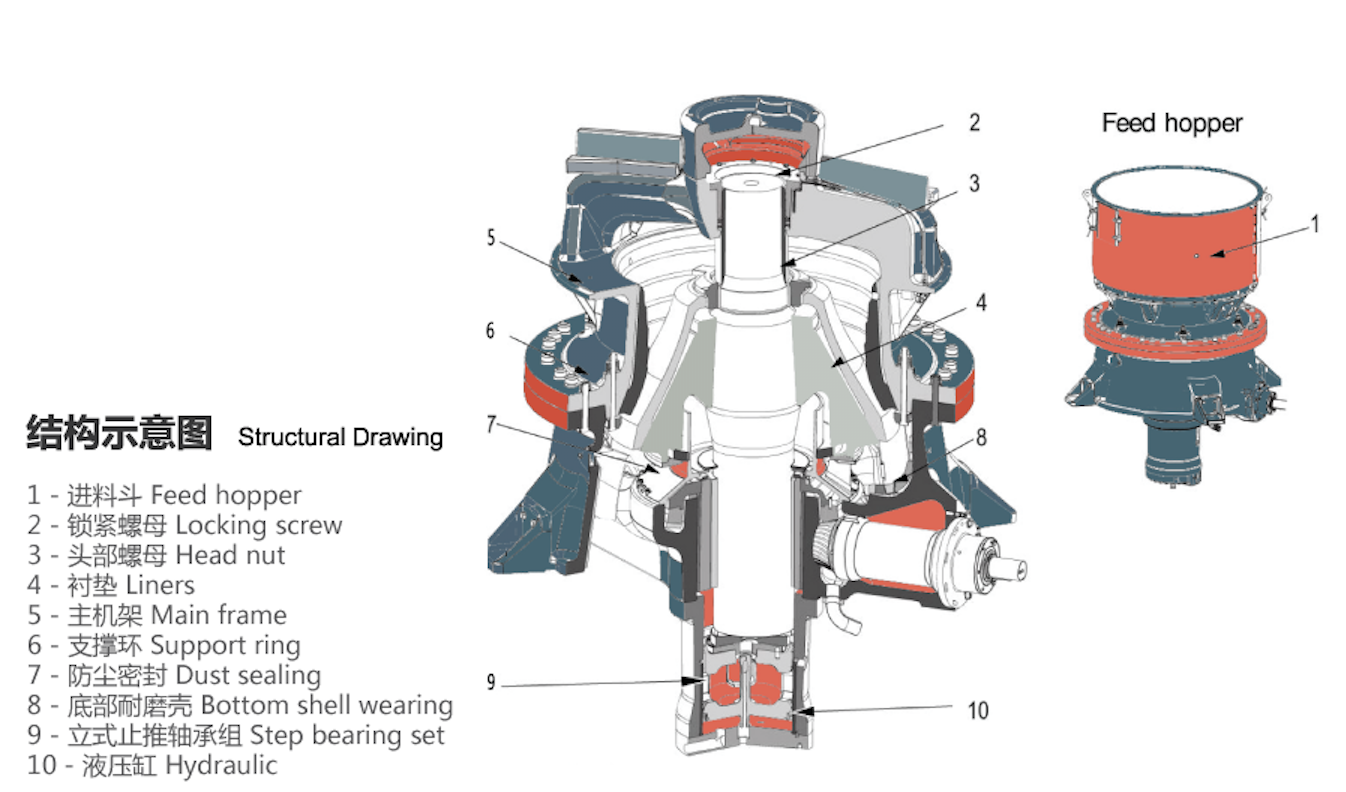

HST Single Cylinder Hydraulic Cone Crusher is a new high-efficiency cone crusher independently researched, developed and designed by MANTO MACHINERY through summarizing advanced American and German technologies about cone crushers. This cone crusher integrates mechanical, hydraulic, electrical, automation and intelligent control technologies, and possesses advanced cone crusher technologies in the world.

HST Single Cylinder Hydraulic Cone Crusher has the characteristics of advanced structural design, excellent crushing capacity, reliability and low production and operation cost. The cone crusher lifts and lowers the mantle through a single hydraulic cylinder, which realizes a variety of functions such as discharge adjustment, cavity cleaning, iron crossing and overload protection. Widely used in the crushing of raw materials in metallurgy, construction and road construction industries, it can crush various ores and rocks medium and above medium hardness. HST Single Cylinder Hydraulic Cone Crusher has huge crushing capacity, reliable and durable. It runs continuously and stably, and the crushing ratio is large, high efficiency, low energy consumption, uniform product particle size, simple and convenient adjustment.

|

| Working Principle |

When HST Single Cylinder Hydraulic Cone Crusher works, driven by the motor, the transmission shaft rotates under the action of belt pulley and triangular belt. The transmission shaft drives the eccentric sleeve to make it rotate around the axis. Meanwhile, the eccentric sleeve forces the movable cone to do pendular movement. This movement makes the movable cone and fixed cone sometimes close to, sometimes far away from the concave. Materials are continuously shocked, squeezed and crushed in the crushing cavity between the concave and mantle. Finally, materials are discharged out of the machine when their fineness reaches the discharging standard. |

Working Principle

Performance

Performance

High Production Efficiency, Strong Holding Capacity

HST Single-cylinder Hydraulic Cone Crusher achieves higher production efficiency and better product quality by matching suitable crushing cavity, eccentric distance and movement parameters. Combined with optimized strength and high-quality components, HST Hydraulic Cone Crusher has bigger holding capacity and crushing ratio as well as stronger throughput capability.

Fully Automatic Control Covering Whole Production Process

The fully automatic control system equipped on the HST Cone Crusher can provide manual control, constant discharge opening control, constant power control and many other operation modes for users to select. It can continuously monitor the internal actual load of the crusher to optimize the use ratio of the crusher and allow it to play its best performance at all times.

Easier for Maintenance, More Effective for Cost Savings

HST Hydraulic Cone Crusher has a simple structure. Almost all checks and maintenances can be done by only taking down the upper rack. The structure can not only make maintenances and checks get easier, but also save maintenance costs a lot. Besides, HST Single-cylinder Hydraulic Cone Crusher is compact on its structure, occupying small floor area, which further cuts expenditures on the foundation building.

Multiple Cavity Types Meet Various Production Needs

HST Hydraulic Cone Crusher has several kinds of standard crushing cavities which can fully meet the secondary, tertiary and even quaternary crushing needs after primary coarse crushing.

Technical Parameters

| Model |

Cavity |

Max. Feed in size MM |

Min. Output size MM |

| HST100 |

C1(Extra Coarse) |

240 |

22 |

| C2(Medium Coarse) |

200 |

19 |

| F1 (Fine) |

135 |

10 |

| F2 (Medium Fine) |

65 |

8 |

| F3(Extra Fine) |

35 |

4 |

| HST160 |

C1(Extra Coarse) |

360 |

25 |

| C2(Medium Coarse) |

300 |

22 |

| C3(Coarse) |

235 |

19 |

| F1 (Fine) |

185 |

13 |

| F2 (Medium Fine) |

90 |

10 |

| F3(Extra Fine) |

50 |

6 |

| HST250 |

C1(Extra Coarse) |

450 |

35 |

| C2(Medium Coarse) |

400 |

29 |

| C3(Coarse) |

300 |

25 |

| F1 (Fine) |

215 |

16 |

| F2 (Medium Fine) |

110 |

13 |

| F3(Extra Fine) |

70 |

8 |

| HST315 |

C1(Extra Coarse) |

560 |

41 |

| C2(Medium Coarse) |

500 |

38 |

| F1 (Fine) |

275 |

16 |

| F2 (Medium Fine) |

135 |

16 |

| F3(Extra Fine) |

65 |

13 |

| HST450 |

C1(Extra coarse) |

560 |

54 |

| C2(Medium coarse) |

465 |

51 |

| HST560 |

F1 (Fine) |

300 |

22 |

| F2 (Medium fine) |

155 |

19 |

| F3(Extra Fine) |

80 |

10 |

| HST750 |

F1 (Fine) |

370 |

25 |

| F2 (Medium Fine) |

195 |

22 |

| F3(Extra Fine) |

85 |

10 |

| Model |

Cavity |

Capacity TPH |

Motor power KW |

| HST100 |

C1(Extra Coarse) |

85-170 |

90 |

| C2(Medium Coarse) |

70-130 |

| F1 (Fine) |

45-115 |

| F2 (Medium Fine) |

35-80 |

| F3(Extra Fine) |

27-60 |

| HST160 |

C1(Extra Coarse) |

120-345 |

160 |

| C2(Medium Coarse) |

105-305 |

| C3(Coarse) |

90-275 |

| F1 (Fine) |

66-210 |

| F2 (Medium Fine) |

65-165 |

| F3(Extra Fine) |

48-105 |

| HST250 |

C1(Extra Coarse) |

255-605 |

250 |

| C2(Medium Coarse) |

215-515 |

| C3(Coarse) |

190-490 |

| F1 (Fine) |

110-395 |

| F2 (Medium Fine) |

115-340 |

| F3(Extra Fine) |

90-255 |

| HST315 |

C1(Extra Coarse) |

335-1050 |

315 |

| C2(Medium Coarse) |

305-895 |

| F1 (Fine) |

170-665 |

| F2 (Medium Fine) |

190-505 |

| F3(Extra Fine) |

205-320 |

| HST450 |

C1(Extra coarse) |

500-1300 |

450 |

| C2(Medium coarse) |

450-1200 |

| HST560 |

F1 (Fine) |

430-1515 |

560 |

| F2 (Medium fine) |

380-1375 |

| F3(Extra Fine) |

270-775 |

| HST750 |

F1 (Fine) |

460-2130 |

750 |

| F2 (Medium Fine) |

525-1605 |

| F3(Extra Fine) |

350-885 |